ISO 9001 Design Verification vs Design Validation

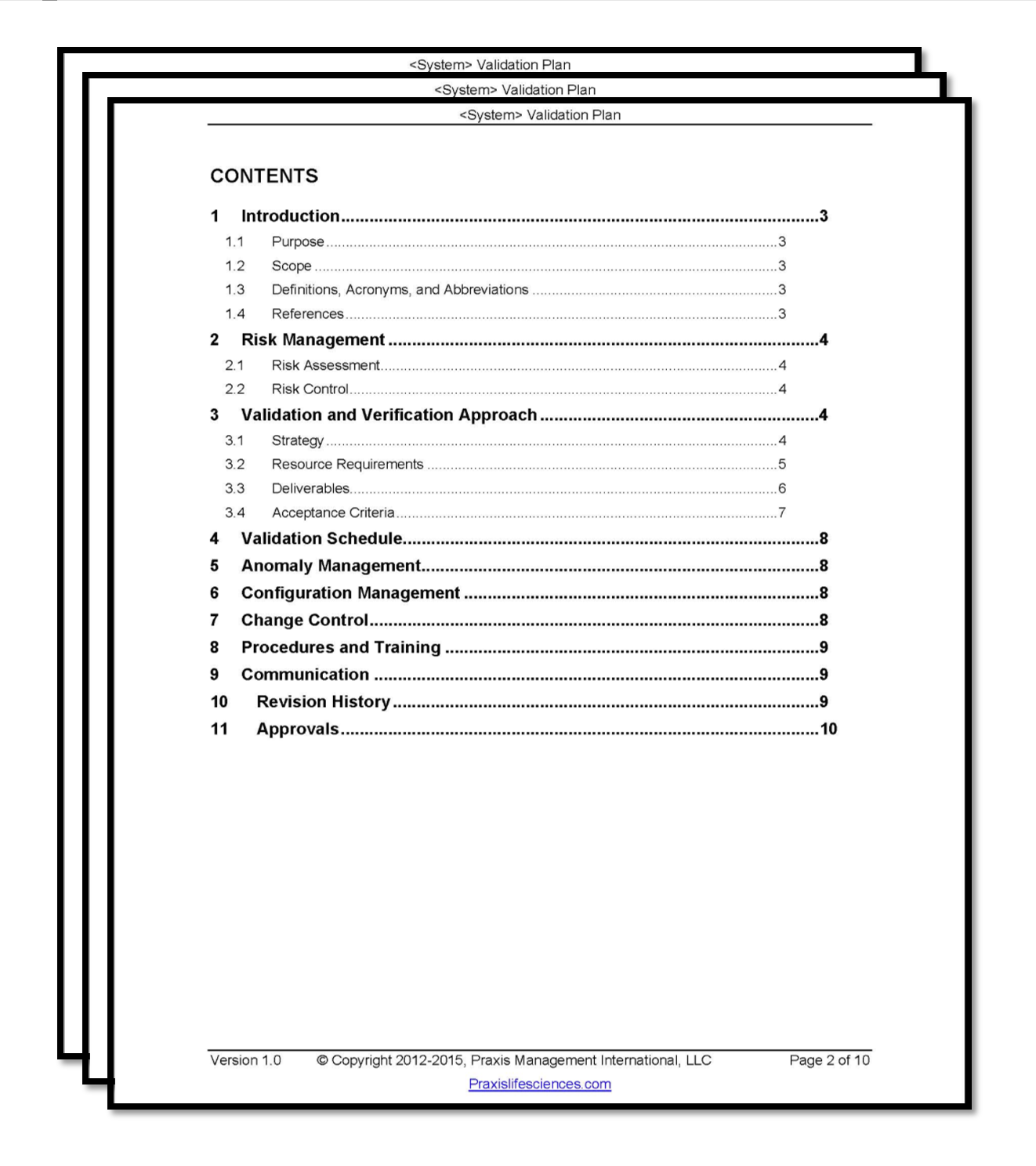

Table Of Content

Jump off the shelves with eye-catching designs that speak to your target audience. Implement your style and tone within every step of the conversion funnel, including a custom web design. Whether creating, modernizing or revitalizing your logo, we will guide you through the process and create bespoke results that deliver. Highlight your brand’s core messaging and style with an on-point logo to transform awareness for your business.

Top 7 product design testing methods (and how to use them effectively)

The purpose is to prove with objective evidence that the product satisfies the documents of user needs. The objective evidence is nothing but any physical proof of the output such as an image, text or audio file which indicates that the procedure has been accomplished. Contact us today to tell us about your project and kickstart the process of growing your brand online. The costs of graphic design services vary depending on the size of a project and where they are delivered. Consistent messaging is crucial in turning random consumer touchpoints into leads that convert.Use your brand book and style guide to craft imagery that is recognizable across all your marketing channels. Portray trustworthiness with on-brand messaging and designs that show professionalism and expertise.

LLMs For Hardware Design Verification - SemiEngineering

LLMs For Hardware Design Verification.

Posted: Mon, 16 Oct 2023 07:00:00 GMT [source]

How Our LA Graphic Designers Deliver Unique Services

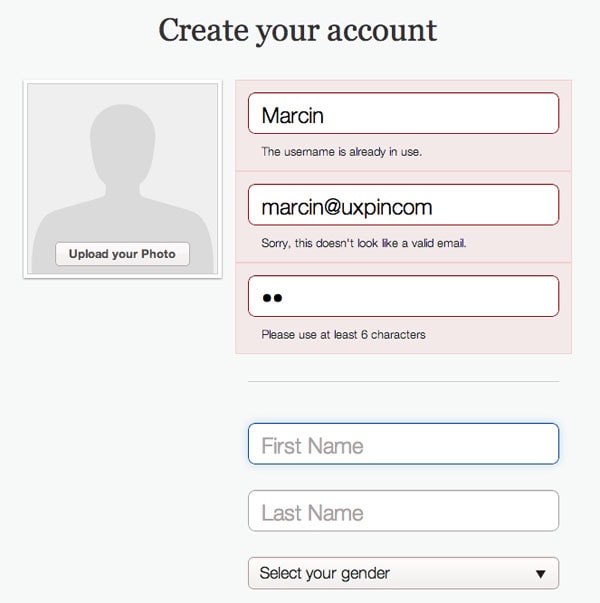

Even if your design validation plan template is great, if you don’t have the right people to implement it, it won’t work. Enterprise products have many short-term and long-term effects on both employees and businesses. Here are some tips and examples to help you design better user experiences.

Design validation methods

Make use of the insights gathered during the validation process to create better future design validation plans. Encourage the team to provide feedback while learning from one another at all times. Design Validation is a process of evaluating the software product for the exact requirements of end-users or stakeholders. The purpose of design validation is to test the software product after development to ensure that it meets the requirements in terms of applications in the user’s environment. Through design validation, you can ensure a user-friendly design that is meaningful for both the users and the business.

You can conduct design validation through user research, and it’s essential to mitigating risk when developing products. The best way to think of design validation versus verification in UX design is to consider the primary objectives of each. While both are necessary in user-centered design to ensure that you create effective solutions, both validation and verification play a role in the design process.

A portable articulated dynamometer for ankle dorsiflexion and plantar flexion strength measurement: a design ... - Nature.com

A portable articulated dynamometer for ankle dorsiflexion and plantar flexion strength measurement: a design ....

Posted: Thu, 14 Dec 2023 08:00:00 GMT [source]

The downside to this approach though is that it takes time to collect the data. With the objectives clearly defined, and a skilled team assembled, the next phase is identifying which validation methods you will use. There are various methods to choose from, such as analytical modelling, simulations, and physical testing. When choosing a method, ensure that it aligns with the goals and constraints of your project.

We gather and leverage information through tons of different research methods to ensure that we’re focused on the biggest user needs and have a solid understanding of them. With your new information in hand, from pre- or post-product launch, start reviewing. Go back through all your user needs, design inputs, and design outputs. Regardless of when you decide to update the product, the process for making that change is the same. It’s a familiar process because it resembles what you did during design and development.

How Do EVT, DVT, and PVT Impact the Manufacturing Process?

If you’re based in one of the locations above or elsewhere, fill in our Request a Quote form to receive a custom quote, consultation and brand audit from our team. At Digital Silk we have bases across the U.S. and beyond, so you do not have to be located in Los Angeles to receive our graphic design services. Enhance your digital presence with features and designs that transform your visual identity online. Kick it all off with a set of discovery calls and onboarding meetings, where we discuss the project itself and research the wider context. By following a well-trodden path we ensure timely deliveries that exceed expectations. Our LA agency delivers branding services across industries and marketplaces.

In this example, design verification checks that your design outputs—such as drawings, specifications, or manufacturing instructions—meet those design inputs. The medical device development tools you choose should add to the accuracy and effectiveness of the work your team is doing, and not add unnecessary overhead to their daily tasks. A good tool provides guard rails to ensure that the important things are always done. It gives your team flexibility to produce ad hoc views and reports to better use (and explore) the data you’ve captured.

These are both essential aspects of ensuring the medical device can be used safely and effectively. This will often require more testing that will be used on production models. To ensure that all requirements are met, a full set of measurement and tests is done on the validation unit.

They develop an engineering-level beta prototype containing all the functionalities of the intended end-user product. However, the prototype is a minimum viable option of the final product, designed review of functionality. As your design ideas take shape, test user responses to clickable prototypes or full-scale product iterations and use a wider range of testing methods, including usability testing, split testing, and user observations. While there are multiple areas of the device lifecycle where verification and validation play a key role, below you will find an overview of design verification and design validation. 3D printing is one of the tools that can support development teams throughout the product development process.

Verifying for accuracy of implementation is just as important as verifying that the right solution was built. After you create a design, verification helps you understand if the solution aligns with the user needs outlined during the validation phase. By the end of the process, you should have a list of design inputs and verification tests for each that will demonstrate that the device does what you intend it to do. You need a typical user to test your product for an objective idea of its performance. User testing is one of the best ways to determine whether the product can serve users' needs. For example, when designing medical devices, you need to comply with the US Food and Drug Administration (FDA) requirements.

Increase bookings and brand reputation with sleek digital and physical branding designs. From website redesign to rebranding, we repositioned FieldEdge as a field management industry leader. Our redesign services, including a new logo and brand book guidelines, supported SNP in growing its digital presence in the biotech market.

This document will list every requirement for the design, identify if the design is compliant or not, and list where this compliance is proven in the documentation. Design validation is gauging the performance of a design before implementing it. In a nutshell, A/B testing is creating multiple versions of the same piece of functionality and then seeing whichever one performs best.

It is used for lab-based user testing with a select group of lead users, to communicate production intent to tooling specialists in subsequent stages, and to act as a demonstrator in the first sales meetings. Rushing to the design verification and validation stages doesn’t actually save you time. It just ensures you’ll spend even more time and energy trying to verify unclear design inputs or validate the poorly defined user needs.

Verification is used to make sure that the design has addressed every requirement, while validation is used to prove that the design can meet the requirements set out for it. A simplified way of understanding the difference between design validation and verification is the former ensures that the right product is being built, while the latter ensures that the product is built right. Jesseca Lyons is a Senior Medical Device Guru at Greenlight Guru and a Mechanical Engineer by trade who loves working with cross functional teams, including both engineering and non-engineering disciplines. She’s spent most of her career gathering and defining requirements for new product design and development in the... That’s why at Greenlight Guru, our QMS platform allows you to create detailed design control objects, link complex configurations, and attach documents with a single click.

Comments

Post a Comment